Oksana Khokhitva

International sales manager

+380 (57) 719 62 05

+380 (57) 719 62 05

+380 (68) 348 78 16

+380 (57) 719 62 05

+380 (57) 719 62 05

Directions of activityimperija.compasta.imperija.comsweets.imperija.comcnc.imperija.comtools.imperija.com

iron

form of quality

01.12.2009

Concept of macaroni press creation.

Macaroni press «Emperor» was made by the engineers of NPO «Metal Empire» based on ten-year experience of equipment production and support manning of macaroni production of world leaders.

A brand new mixing method with automatic flour and water measuring device helps to obtain dough of "grit" consistence and prevents flour from milling in extrusion barrel. Dough maker design has a vacuum pump and with minimal energy consumption during all technologic cycle stages it maintains vacuum at the level 0,02 MPa, starting from raw material measuring.

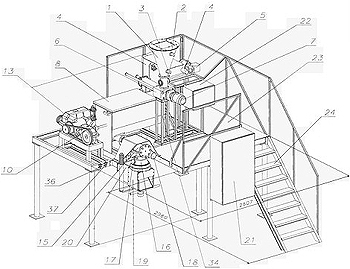

1 — flour supply bin;

2-3 — flour level sensors;

4 — water meter;

5 — flour meter drive;

6-7 — mixer;

8 — dough mixer bin;

9 — worm gear;

10 — dough mixer drive;

15 — extrusion barrel;

16 — pressing head;

17 — thermometer;

19 — cutting-off device;

20 — product blower;

21 — control cabinet;

22 — small control cabinet;

23 — observation site;

24 — ladder

| Output by raw product | 400 kg/h |

| Matrix diameter | 350 mm |

| Consumed power | 14 kW |

| Network parameters | 3х380 В,50 Hz |

| Press weight | 1700 kg |

| length | 2 800 mm |

| width | 4 000 mm |

| height | 4 000 mm |

| Space required for mounting | 12-15 m2 |

|

Flour sifting-and-dressing machine of rough cleaning with conveyor auger and automatic impurities separation |

2 500 USD |

| Flour sifting-and-dressing machine of fine cleaning with conveyor auger | 3 500 USD |

|

Press «Emperor» |

80 000 USD |

|

***A set for “longcut” production (spaghetti). |

50 000 USD |

| Optional: or drying cabinet — 8ps | 44 800 USD |

| or conveyor drying unit | |

| Installation supervision (depending on the area and TS of the client) | 10-25% |

| Conditions of warehouse delivery in Kharkiv, Ukraine | FCA |

|

Warranty on the press 1 year. Time of manufacture - from 5 months. |

Configuration and service:

Auxiliary equipment:

Upon the flour loading to the receiving bin and flour sifting-and-dressing machine startup the flour is bolted and the waste as well as metallic impurities are separated. Feeding flexible auger ensures flour supply to the next operating body of the macaroni line, level sensors indicate flour presence in the bin.

Upon the flour loading to the receiving bin from auger feeding of the and flour sifting-and-dressing machine of rough cleaning the flour level sensors activate the bolter drive vibrator, where the flour is bolted and the waste and metallic impurities are separated, feeding auger ensures the supply to the next operating body of the macaroni line.

When the flour is supplied to the receiving bin of the macaroni press from the flour sifting-and-dressing machine of fine cleaning the sensors of flour level of receiving bin are activated and the light indication signals partial operation availability to the operator. Upon the opening of the water supply tap in the system of macaroni press water treatment it is filled, upper level valve turns off its supply and lower level sensor signals press operation availability.

Then measuring devices (patent application of December 12, 2003) measure water and flour in a certain proportion for the dough mixer (Patent application for the unit and dough preparation mode: PCT/UA13/00055 (patents in 162 countries in the world), application 2003054866), which prepares dough for extrusion through installed matrix (patent for alignment of product length by matrix and implementation of this method № 2003131919/13 (034178)).

Activation of press vacuum assembly, self-design, is performed during the raw material measuring. During the stage of extrusion electric motor of auger supplying prepared and pressed raw material to the matrix with draw plates is activated (patent №2197875 for macaroni draw plates — mode, method and structure), used for the dough mass forcing through to obtain wet products. Cutting device knives cut the dough piece into certain length products which are passed to a tray or conveyor belt.

+380 (57) 719 62 05

+380 (57) 719 62 05

+380 (68) 348 78 16

+380 (57) 719 62 05

+380 (57) 719 62 05

Callback